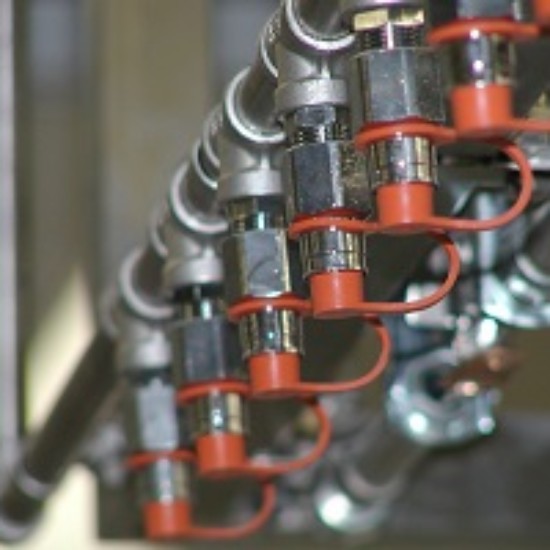

Kitchen suppression systems are designed, tested, and approved to provide fire protection for commercial kitchen cooking appliances, hoods, and ducts. The suppression systems consist of an agent storage tank, manual release station, an automatic releasing mechanism, and supply piping that directs the agent to nozzles strategically positioned at heat sources in the kitchen.

NFPA 17 requires that every 12 years the agent-holding tank, whether it is a pressurized or non-pressurized system tank, must be pulled out of service to be tested.

For all systems, the agent storage tank must be pressure tested to ensure the integrity of the cylinder. There are many types and manufactures of kitchen commercial wet chemical systems, each one has different test pressures for the cylinder, which are set by the manufacturer. Once filled with water, and sometimes oil, the cylinder is capped off, then pressurized to the manufacture test pressure and held at that pressure for no less than 1 minute. These systems are often tested to almost two times the service pressure.

On a non-pressurized system, there is a cartridge that pushes the agent out of the cylinder. This cartridge is replaced every 12 years. In some instances, these systems can have a burst disc that would need to be replaced before the 12-year hydrostatic test is scheduled.

Pressurized systems have valve stems, O-rings, and pins that need to be replaced. This is called a rebuild kit.

Once all of the cylinders are tested, dried, and documented they get filled back up with the proper wet chemical agent and put back into service if there is not any issues with the test pressures. All systems, both pressurized and non-pressurized, get new agent during a 12-year hydrostatic test. For certain suppression systems, hoses will need to be replaced at the 12-year hydrostatic test.

A1 is a leading expert on the latest technology in life safety. To find out more information or to ask a question, click here or call us at 1-800-859-6198.